TS21 Tank-System

The laboratory experiment "TS21 Tank System" contains |

|

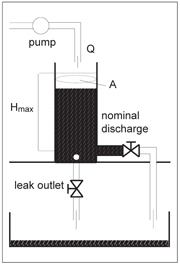

The nonlinear controlled

member consists of a plexiglass

cylinder T of cross-sectional

area A. The liquid (distilled

water) flowing from T is

collected in a reservoir from

which the pump supplies the

tank T. |

|

The associated documentation contains appropriate instructions for the installation, the theoretical background of the plant, operating instructions for the analog controller, the technical data, guidelines for a practical course and solutions. This standard version is therefore suitable as a practical experiment for students in all stages of control engineering. As extension for the laboratory experiment "Tank-System TS21" the following options are available:

There are separate data sheets available for the options 21-07 and -09. Technical data are subject to change (Date 9-March-2024) |